One of the key maintenance tasks is pulley laser alignment. Added loads are rendered when pulleys are improperly positioned. The goal of belt alignment is to line the grooves of the driven and drive pulleys to minimize wear on the belts. The lifespan of bearings and belts is increased by proper alignment, lowering noise and vibration levels and conserving energy.

The driven and driving pulleys may be out of alignment by an angle in either the horizontal or vertical plane. As seen from the edge of the pulleys, it can also be parallel with one pulley offset from the other. In reality, many belt misalignments can coexist simultaneously. A new belt won’t survive any longer than the one it replaced until belt misalignment is fixed.

The traditional method and laser method are both used to align pulleys. Traditional alignment techniques are swift but frequently ineffective. Mechanical equipment like tape, measures, straightedges, wire, string, gauges, feelers, spirit levels, and calibrated cones are used in these techniques.

Aligning the Belt and Pulleys: How Important Is It?

A crucial component of routine, preventative maintenance is the alignment of the pulleys. There are numerous reasons to guarantee that maintenance workers routinely check pulley alignment. These are a few of the factors that make pulley alignment crucial.

Pulleys and belts are used to transfer power from drive motors to a range of industrial equipment. In order to avoid costly repairs and machine downtime, pulley alignment needs to be regularly examined and changed.

Whether the misalignment is parallel or angular, improperly aligned pulleys may cause excessive wear and early component failure. In addition, pulley misalignment may be the root cause of half of all rotating machine problems, according to some estimates. Therefore, a substantial percentage of failures and the associated costs can be avoided by using good pulley alignment.

A misaligned pulley frequently causes belt failure. Additionally, it frequently causes seals and bearings to break too soon. A shaft or pulley alignment issue that damages seals can frequently be linked to lubrication issues. In such situations, changing the seal will only be a temporary fix because the seal will probably keep failing until the alignment issue is resolved. Additionally, misalignment may result in vibration, noise, and even shaft damage.

An investment in your equipment and your bottom line is maintaining good shaft and pulley alignment on any rotating machinery. Pulley misalignment, however, is a simple diagnosis and repair issue that can save a lot of money in future maintenance costs and equipment downtime.

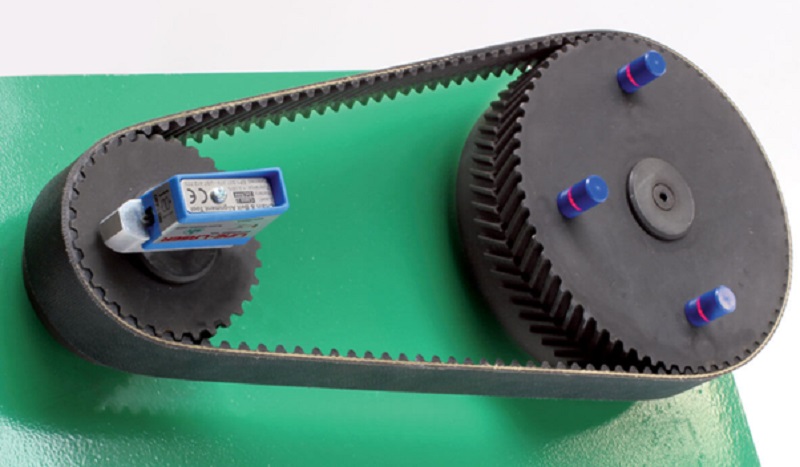

EASY-LASER ALIGNMENT SYSTEMS PULLEY ALIGNMENT TOOLS

People look for equipment for belt or V belt alignment, sheave alignment, and chain or sprocket alignment when they conduct online searches for pulley alignment tools. But, of course, everything is based on how the machinery is used. The most frequently used word, though, is undoubtedly pulley alignment tools. Surprisingly, many businesses still don’t have or employ instruments or procedures for pulley alignment. The Easy-Laser D90 Pulley Alignment Instrument is a less expensive, universally used tool. However, some businesses continue to align pulleys or belts with a string or straightedge, which is still likely the most typical method used today. Using a piece of string to line up two pulleys or sheaves should be a thing of the past, given the advancements we have achieved in maintenance. However, it has a place in the past.

According to some industry experts, a belt drive should have a 7-year operational life. Make sure your team uses the appropriate tool for the job if you want to optimize the results from your belt drives. We supply digital products like the Easy-Laser XT190 BTA Pulley Alignment Tool, which generates a PDF report, and low-cost laser pulley alignment equipment and systems. The free Easy-Laser XT Laser Alignment app can also be used with this instrument.

To help the business run more efficiently, Benchmarkmark PDM is dedicated to providing you with the best industrial products. To inspect and adjust the shafts and pulleys on your rotating machinery, use one of our several Pulley laser alignment instruments. Then, get in touch with us immediately to place an order or learn more.

Common Myths and Misconceptions About Portable Welding Fume Extractors Debunked

Common Myths and Misconceptions About Portable Welding Fume Extractors Debunked  Enhancing Industrial Efficiency With LM Slide Bearings

Enhancing Industrial Efficiency With LM Slide Bearings  Benefits Of Industrial Ice Blasting Services

Benefits Of Industrial Ice Blasting Services  Understanding low-intensity shockwave therapy for ED

Understanding low-intensity shockwave therapy for ED  Debt Settlement Attorney: Expert Guidance for Financial Relief

Debt Settlement Attorney: Expert Guidance for Financial Relief  The Ultimate Home Maintenance Checklist: Keeping Your Home in Top Shape

The Ultimate Home Maintenance Checklist: Keeping Your Home in Top Shape  Why Trade Show Signs Are Crucial for Your Business Success

Why Trade Show Signs Are Crucial for Your Business Success